| Specification | Unit | TX-110B | TX-110C | TX-110D | |

| Table | |||||

| Table size | mm | 1010*1320 | 1010*1320 | 1010*1320 | |

| Max.load of table | kg | 5000 | 5000 | 5000 | |

| T-slot size | mm | 7-22*125 | 7-22*125 | 7-22*125 | |

| Worktable positioning precision | ″ | 12 | 12 | 12 | |

| Capacity | |||||

| X-axis travel | mm | 850 | 1200 | 1800 | |

| Y-axis travel | mm | 900 | 900 | 1200 | |

| Z-axis travel | mm | 1100 | 1100 | 1100 | |

| W-axis travel | mm | 550 | 550 | 550 | |

| Distance from spindle center to worktable surface | mm | 5-905 | 5-905 | 5-1205 | |

| Max.boring diamter | mm | Φ240 | Φ240 | Φ240 | |

| Swing plate tool post max.processing end diameter | mm | Φ630 | Φ630 | Φ630 | |

| Max.drilling diameter | mm | Φ50 | Φ50 | Φ50 | |

| Spindle | |||||

| Spindle diameter | mm | Φ110 | Φ110(Φ130) | Φ110(Φ130) | |

| Spindle speed range | rpm | 12-950 | 12-950 | 12-950 | |

| Spindle speed step | steps | 18 | 18 | 18 | |

| Spindle taper | Morse6 | Morse6 | Morse6 | ||

| Spindle max.output torque | N.m | 1100 | 1100 | 1100 | |

| Max.axial force | N | 13000 | 13000 | 13000 | |

| Swing plate | |||||

| Diameter | mm | Φ550 | Φ550 | Φ550 | |

| Tool post travel | mm | 160 | 160 | 160 | |

| Speed range | rpm | 4-160 | 4-160 | 4-160 | |

| Speed step | steps | 16 | 16 | 16 | |

| Max.torque | N.m | 1100 | 1100 | 1100 | |

| Feeding | |||||

| Rapid feeding speed | X/Y/Z | mm/min | 1800 | 1800 | 1800 |

| W | mm/min | 3600 | 3600 | 3600 | |

| Swing plate tool post | mm/min | 1120 | 1120 | 1120 | |

| Spindle each revolution feeding scope of spindle box and workbench | mm | 0.025-8 | 0.025-8 | 0.025-8 | |

| Swing plate each revolution feeding scope of spindle box and workbench | mm | 0.075-24 | 0.075-24 | 0.075-24 | |

| Swing plate each revolution feeding scope of radial tool post | mm | 0.05-16 | 0.05-16 | 0.05-16 | |

| Machine weight | kg | 10700 | 13500 | 16500 | |

| Power capacity | Kva | 35 | 35 | 35 | |

| Machine dimension | mm | 5016*2627*2788 | 5016*3149*2788 | 5016*3867*3148 | |

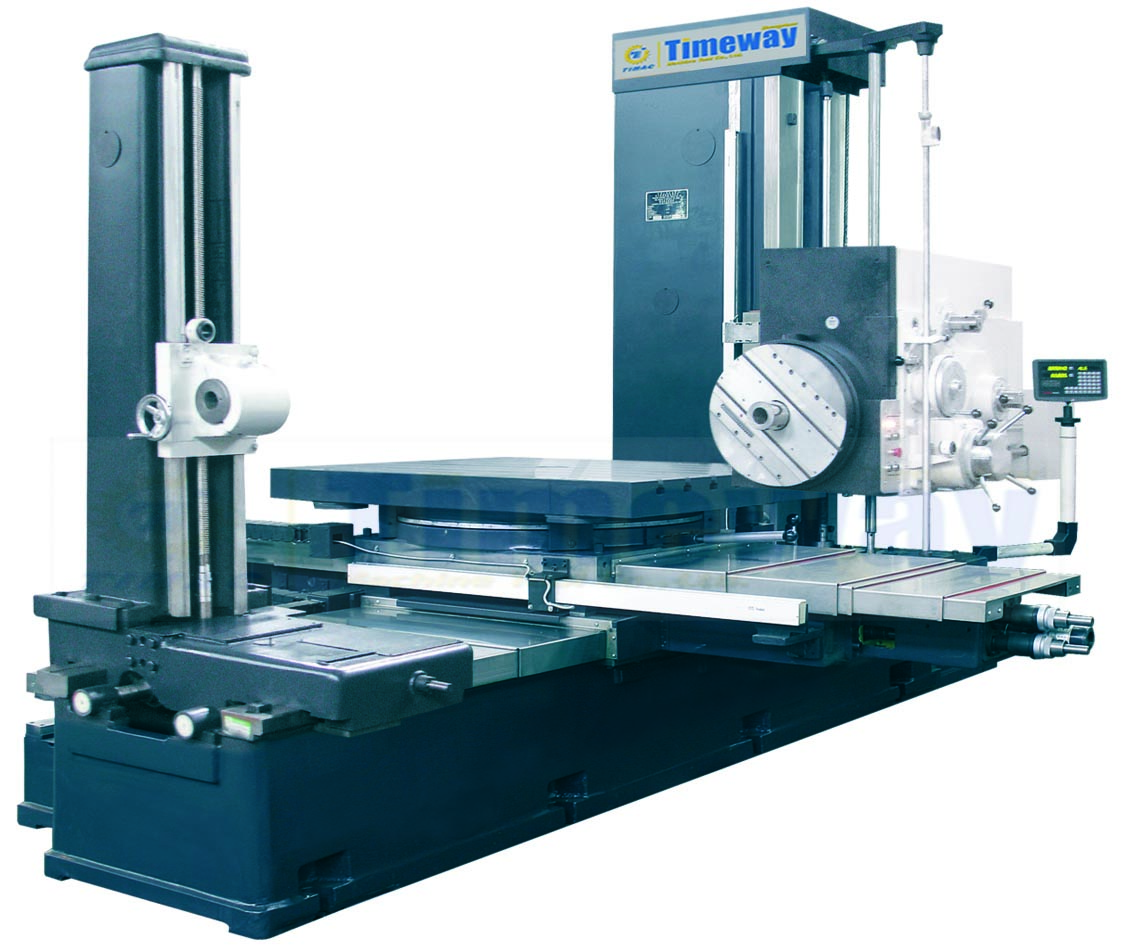

Horizontal Boring Milling Machine (TX-110B, TX-110C, TX-110D)

Features:

1. TX-110 series horizontal boring milling machine is ordinary horizontal milling and boring machine, it adopts enhanced boring bar in the similar machine tools. It is suitable mainly for the plane milling and hole-series processing of case parts.

2. The machine tool is characterised by spindle system strong rigidity, power cutting, high processing efficiency.

3. The spindle box end is equipped with swing plate with the radial tool head, that can boring large hole and plane.

4. Choose hanging wheel rack, screw thread processing can be performed.

5.Max.load of worktable is 5T.

TX-110B:

1. The fundamental large parts adopt rectanglar guideway, such as bed, column, upper saddle, lower saddle, guarantee machine good stability.

2. The guideway adopt automatically centralized quantitative lubrication.

3. The machine is configurated standardly to X,Y axis digital read-out device.

4. Table adopts four single pin positioning structure,accurate positioning.

TX-110C:

The fundamental large parts adopt rectangle guideway,such as bed,column,upper saddle,lower saddle,lathe bed has inlaid steel hardening auxiliary guide rail,machine has good stability,the X coordinate schedules is bigger.

TX-110D:

The fundamental large parts adopt rectangle guideway, such as bed,c olumn, upper saddle, lower saddle, lathe bed uses disconnect-type auxiliary guide with inlaid steel hardenig, machine has good stabilit, the X coordinate schedule is bigger, machine is equipped with back column.