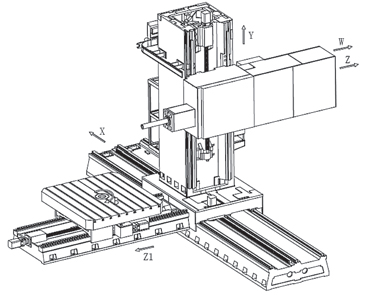

| Specification | Unit | FBC-130 | FBC-160 | FBC-200 | |

| Capacity | |||||

| Column transverse travel(X) | m | 4/6/8/10/12/15 | 4/6/8/10/12/15 | 6/8/10/12/15 | |

| Headstock vertical travel(Y) | mm | 2500/3000/3500 | 3000/3600/4000/4500 | 3500/4000/4500/5000/6000 | |

| Square ram travel(Z) | mm | 1000 | 1250 | 1250 | |

| Boring spindle axial travel(W) | mm | 800 | 1000 | 1250 | |

| Max.boring diameter | mm | Φ500 | Φ600 | Φ700 | |

| Max.drilling diameter | mm | Φ50 | Φ60 | Φ80 | |

| Spindle | |||||

| Boring spindle diameter | mm | Φ130 | Φ160 | Φ200 | |

| Milling spindle diameter | mm | Φ240 | Φ260 | Φ330 | |

| Spindle taper | ISO NO.50 | ISO NO.50 | ISO NO.60 | ||

| Boring spindle speed range | rpm | 3-2000 | 3-1600 | 3-1600 | |

| Boring spindle output torque | N.m | 3543/4885 | 5982/8380 | 18800 | |

| Milling spindle output torque | N.m | 4900 | 8300 | 22000 | |

| Spindle motor power | kw | SIEMENS:37/51 | SIEMENS:60/75 | SIEMENS:100 | |

| Ram cross-sectional area | mm | 450*500 | 450*500 | 530*600 | |

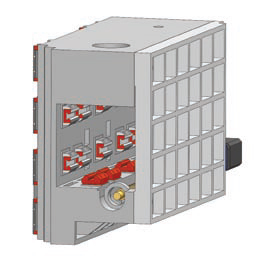

| Tool Magazine | |||||

| Capacity | T | 60 | 60 | 60 | |

| Tool change type | Optional | Optional | Optional | ||

| The time of tool change | sec. | 15″ | 15″ | 20″ | |

| Max.length of tool | mm | 400 | 400 | 500 | |

| Max.diameter of tool | mm | Φ250 | Φ250 | Φ320 | |

| Max.weight of tool | kg | 25 | 25 | 50 | |

| Feeding | |||||

| Feeding speed(X/Y/Z/W) | mm/min | 1-5000 | 1-5000 | 1-5000 | |

| Rapid feeding speed(X/Y/Z/W) | mm/min | 6000 | 6000 | 6000 | |

| Accuracy | |||||

| Positioning accuracy | X/Y | mm | 0.015/1000 | 0.015/1000 | 0.015/1000 |

| Z1 | mm | 0.015/1000 | 0.015/1000 | 0.015/1000 | |

| Z/W | mm | 0.015/1000 | 0.015/1000 | 0.015/1000 | |

| Repeat positioning accuracy | X/Y | mm | 0.008/1000 | 0.008/1000 | 0.008/1000 |

| Z1 | mm | 0.008/1000 | 0.008/1000 | 0.008/1000 | |

| Z/W | mm | 0.008/1000 | 0.008/1000 | 0.008/1000 | |

| Machine weight | kg | 102000 | 124000 | 180000 | |

| Power capacity | Kva | 128 | 128 | 150 | |

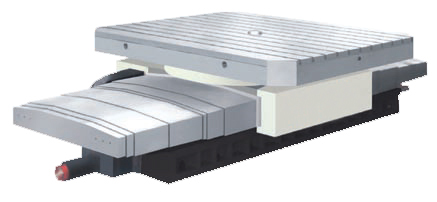

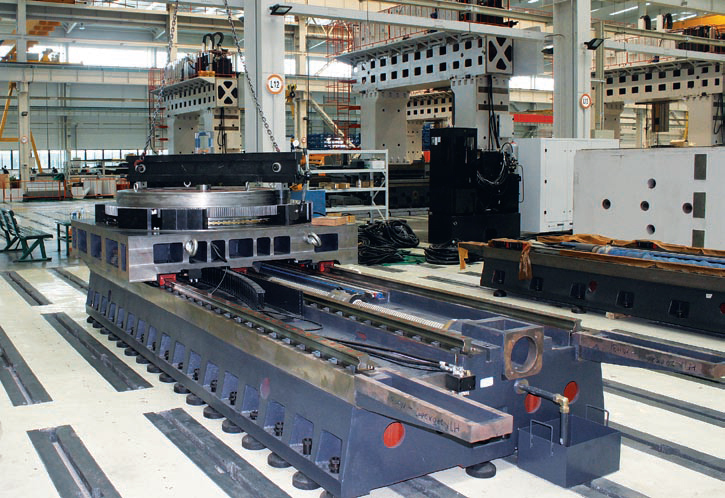

Technical parameters of CNC moving rotary table:

| Specification | Unit | MRT200*220 | MRT220*260 | MRT300*350 |

| Table size | mm | 2000*2200 | 2400*2600 | 3000*3500 |

| Bench height | mm | 1400 | 1495 | 1880 |

| T-slot size | mm | 9-28-200 | 9-36-250 | 9-42-320 |

| Worktable straight travel | mm | 2000 | 2500 | 3000 |

| Worktable swing angle | ° | 360 | 360 | 360 |

| Positioning precision | ″ | ±5 | ±5 | ±10 |

| Repeat positioning precision | ″ | ±3 | ±3 | ±6 |

| Max.load of worktable | kg | 30000 | 40000 | 65000 |

| Worktable weight | kg | 18000 | 22000 | 35000 |

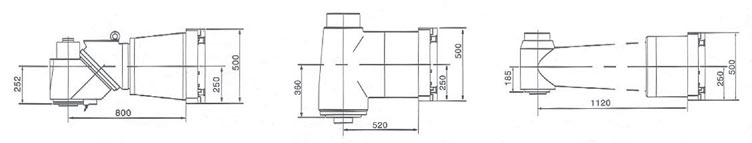

Technical parameters of CNC swing plate:

| Specification | Unit | SP-600 |

| Table diameter | mm | Φ600 |

| Slide travel | mm | 0-200 |

| Max. swing over carriage | mm | Φ1000 |

| Max.speed | r/min | 250 |

| Radial force | N | 1000 |

| Positioning precision of straight motion | mm | 0.045 |

| Repeat positioning precision | mm | 0.03 |

| The average reverse value | mm | 0.025 |