| Specification | Unit | VDK6300 | VDK8000 | VDK10000 | VDK12500 | VDK16000 |

| Max.machining diameter | mm | 6300 | 8000 | 10000 | 12500 | 16000 |

| Diameter of table | mm | 5700/6000 | 7100 | 7100/8000 | 8000/10000 | 8000/10000 |

| Max.machining height | mm | 3150/3500/4000/4500/5000 | 4000/4500/5000/5500 | 4000/4500/5000/5500/6000 | 5000/5500/6000 | 5000/6000/6500 |

| Max.weight of workpiece | t | 63/80/100/150 | 125/200/300 | 125/200/300 | 250/300/400 | 250/500/600 |

| Horizontal stroke of head | mm | -50-3400 | -50-4400 | -50-5400 | -50-6500 | -50-8400 |

| Cutting force of right head | kN | 80/100/125 | 100/125 | 100/125 | 125/160 | 125/160 |

| Cutting force of left head | kN | 63/80/100 | 80/100 | 80/100 | 100/125 | 100/125 |

| Max.torque of table | kN.m | 150/315/500 | 500/640 | 640 | 640 | 800 |

| Section of ram | mm | □280/□320/□400 | □320/□400 | □320/□400 | □400/□460 | □400/□460 |

| Vertical stroke of ram | mm | 2000/2500 | 2000/2500/2750 | 2500/2750/3000 | 2500/2750/3000 | 2750/3000/3500 |

| Power of main transmission motor | kw | 90/110 | 90/110 | 132/160 | 132/160 | 132/160 |

| Rotating speed of table | rpm | 0.32-32/0.25-25 | 0.25-25/0.2-20 | 0.2-20/0.25-25 | 0.2-20/0.16-16 | 0.16-16 |

| Rapid speed moving of head | mm/min | 4000 | 4000 | 4000 | 4000 | 4000 |

| Guideway pairs of table | Hydrostatic | Hydrostatic | Hydrostatic | Hydrostatic | Hydrostatic |

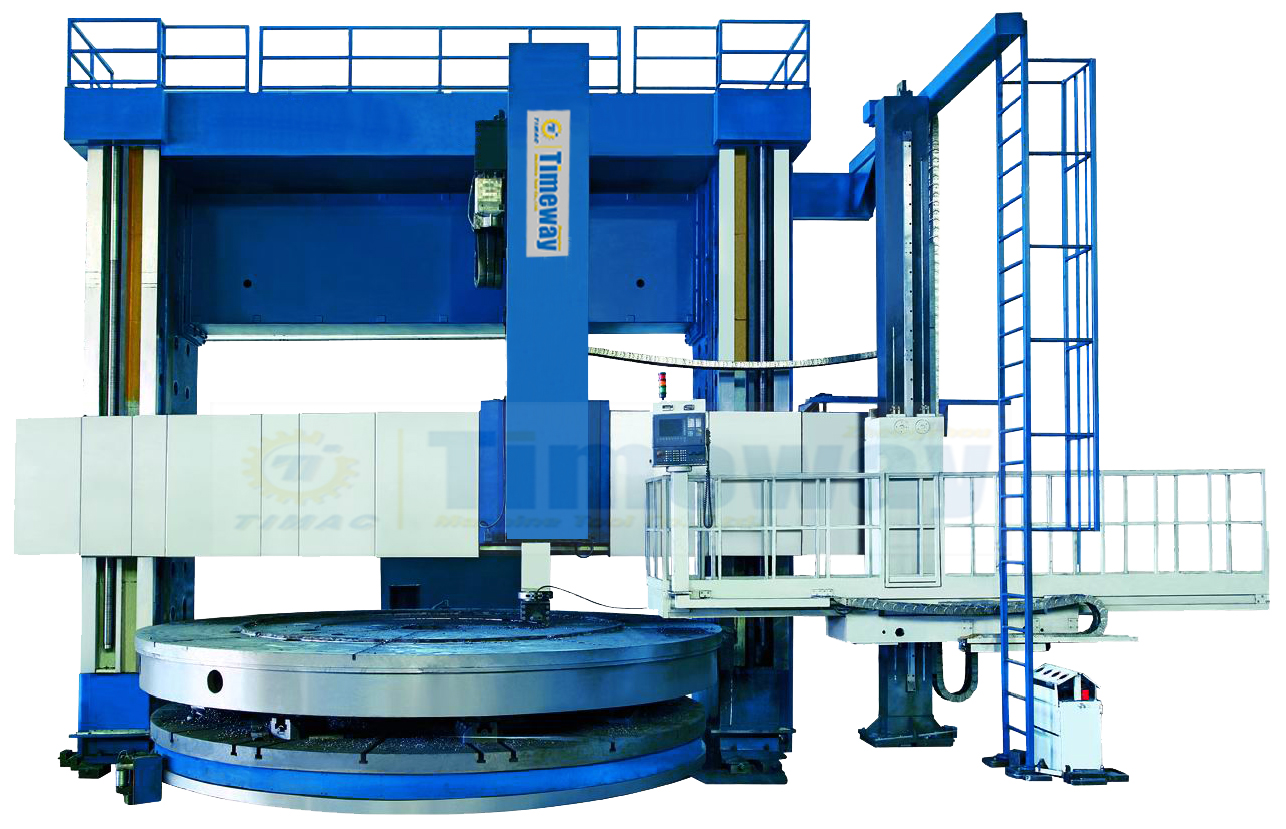

Large CNC Double Column Vertical Lathe

Features:

Performance:

1. The series machine is special item solve large span, super large duty vertical swing platform design manfacture technique, super wide, super long workpiece's machining process etc a set key technique.

2. It is adopted torque plate, unloading rail, anti-bending rail and anti-deformation technique to assure large span's cross rail horizontal accuracy stability.

3. Table is adopted new type connecting tachnical structure, three sets bearing spindle structure, mature single story, double story horizontal guideway and oil film testing technical, which is assure that table large loading, high accuracy stability running.

4. Gantry moving machine is adopted synchronistic servo technical to assure gantry movement, feed correct stability.

5. The serial machine can supply high accuracy, high rotating speed products with milling, boring thread, grinding and kinds tools handle etc function. Machining efficiency is improved.

Main parts structure:

Column: Adopting double wall structure via aging treatment,g uideway via precision finishing has high strength and high rigidity and good vibration resistance. Double shaft extending motor is adopted, synchronization protect function to assure left, right two pieces T type screw lead synchronistic running.

Turning main transmission: Turning main transmission gearbox adopt vertical shaft structure, motor is equipped on the top of main gearbox which can aviod the oil leakage due to the motor hung upside down.

Crossrail: Double story mode big scale section design and pre-deformation process,anti-bending,anti-torque rigid of cross rail is increased, which assure stability for cutting. Unloading rail structure can reduce weight of cross rail capacity head, pressure of cross rail guideway surface is reduced and deformation of cross rail.

Head: It is adopted square forging steel ram to realize strength cutting, adopted double balance oil cylinder head's mode, ball screw is driven by servo motor via low clearance reducer, accuracy of head is improved.

Table: The spindle is fixed mode short spindle structure, table is adopted new type symmery connection structure, three sets bearing spindle structure, mature monolayer, double deck constant flowing hydrostatic guideway and oil film testing technique, with assure table large loading, high accuracy calm running.