| Specification | Unit | AL-1250 | AL-1600 | AL-1800 | AL-2000 | AL-2300 | ||

| Capacities | Swing over bed | mm | 1250 | 1600 | 1800 | 2000 | 2300 | |

| Swing over cross slide | mm | 900 | 1250 | 1450 | 1650 | 1900 | ||

| Max. length of workpiece | mm | 3000/4000/5000/6000/8000/10000/12000/14000/16000/18000 | ||||||

| Max. length of turning | mm | 2800/3800/4800/5800/7800/9800/11800/13800/15800/17800 | ||||||

| Width of bed | mm | 1100 | ||||||

| Max. torque of spindle | N.m | 16966 | ||||||

| Max. cutting force | N | 50000 | ||||||

| Max. force of longitudinal | N | 20000 | ||||||

| Max. weight of workpiece | kg | 16000 | ||||||

| Spindle | Dia. of spindle thru hole | mm | 100 | |||||

| Taper hole of spindle | Metric 140 | |||||||

| Number of forward turning | 21kinds | |||||||

| Number of reverse turning | 12kinds | |||||||

| Spindle speed | Forward | r/min | 3.15~315 | |||||

| Reverse | 3.5~291 | |||||||

| Feed motion | Number of feeds per revolution | (longitudinal/transverse)56/56 | ||||||

| Feed per revolution | Longitudinal | mm | 0.1~12(0.004"~0.473") | |||||

| Transverse | mm | 0.05~6(0.002"~0.236') | ||||||

| Upper tool-post | mm | 0.025~3(0.001''~0.118") | ||||||

| Number and range of metric thread | mm | 44kinds; 1~120mm | ||||||

| Number and range of inch thread | TPI | 31kinds; 28~1/4TPI | ||||||

| Number and range of module thread | mm | 45kinds; 0.5~60mm | ||||||

| Number and range of diametrical pitch thread | DP | 38kinds; 1/2~56DP | ||||||

| Tool post | Size of tool shank | mm | 50x50 | |||||

| Tool post swing range | ±90° | |||||||

| Max. travel of cross slide | mm | 740 | 850 | 900 | 900 | 900 | ||

| Max. travel of top slide | mm | 360 | ||||||

| Rapid of tool post | mm/min | Longitudinal:3740, Transverse:1870, Top slide:935 | ||||||

| Tailstock | Dia. of tailstock quill | mm | 260 | |||||

| Travel of tailstock quill | mm | 300 | ||||||

| Taper hole of tailstock quill | Metric 80# | |||||||

| Others | Main motor power | kw | 30 | |||||

| Power of tool post rapid move motor | kw | 1.5 | ||||||

| Power of cooling pump | kw | 0.15 | ||||||

| Machine overall dimension | Length | mm | 6120/7120/8120/9120/11120/131120/15120/17120/19120/21120 | |||||

| Width | mm | 2058 | 2130 | 2330 | 2330 | 2330 | ||

| Height | mm | 2200 | 2380 | 2480 | 2580 | 2730 | ||

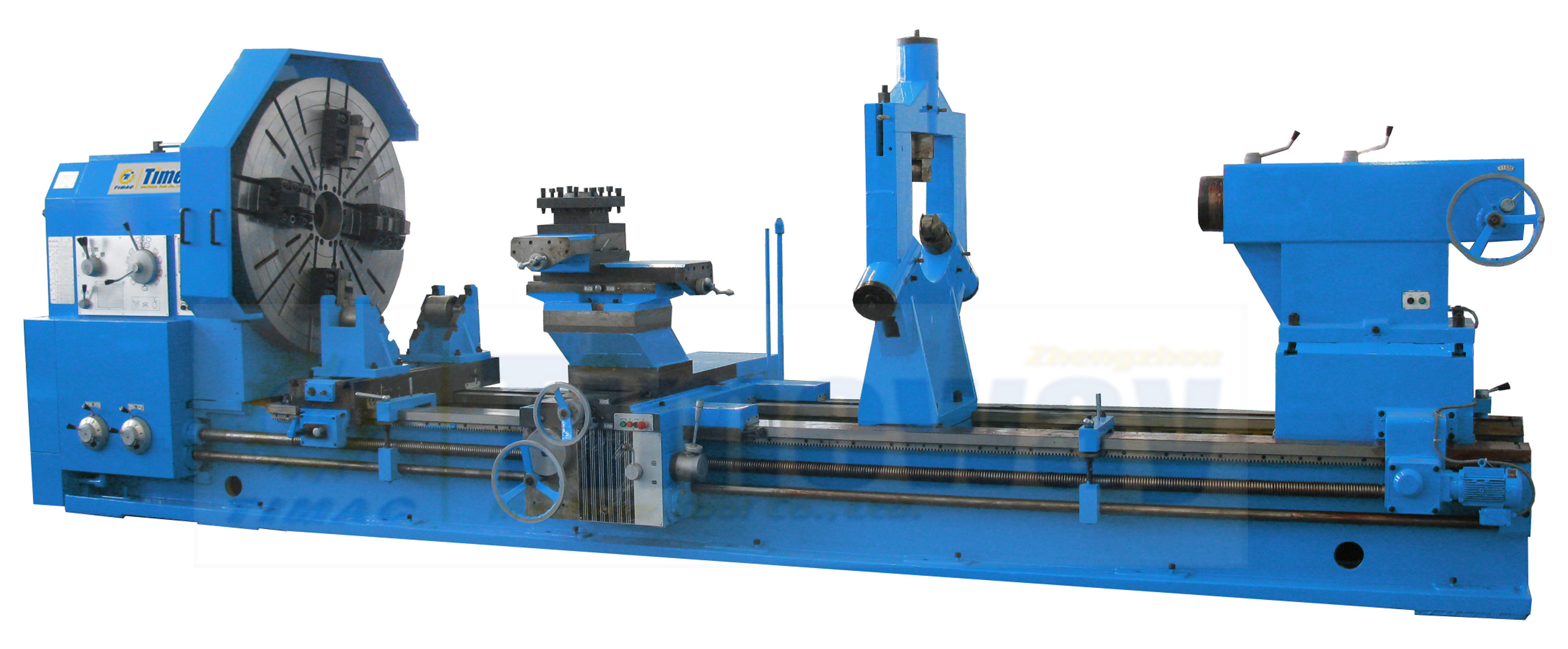

Heavy-duty Horizontal Lathe (AL-1250, AL-1600, AL-1800, AL-2000, AL-2300)

Features:

1. This series heavy duty lathe adopts 1100mm wide rectangular induction hardened and ground bed guide ways, so of excellent stability, high rigidity, and with maximum bearing of 16 tons between centers.

2. The main spindle is of precision roller bearings 3-point supporting structure. Saddle guide ways with Teflon belt coated, rotating tailstock quill structure to minimize friction and heat generation.

3. These machines are suitable for various turning works, such as turning of external and internal cylindrical surfaces, end faces, and turning of metric or inch threads, modular threads and diametrical pitch threads, etc.

4. Motorized short taper turning could be done by the top slide independently, and long taper’s motorized turning could be done by top slide combined with longitudinal feed. Further more, these lathes can also carry out drilling, trepanning and boring processes, etc.

Standard accessories:

4 jaw chuck, Steady rest, Follow rest, Dead center, Oil gun, Coolant system, Working light, General tools, Foundation bolts, Operation manual (English edition).

Optional accessories:

2/3-axes digital readout system(DRO), Grinding attachment, Taper turning attachment, CE execution