Features:

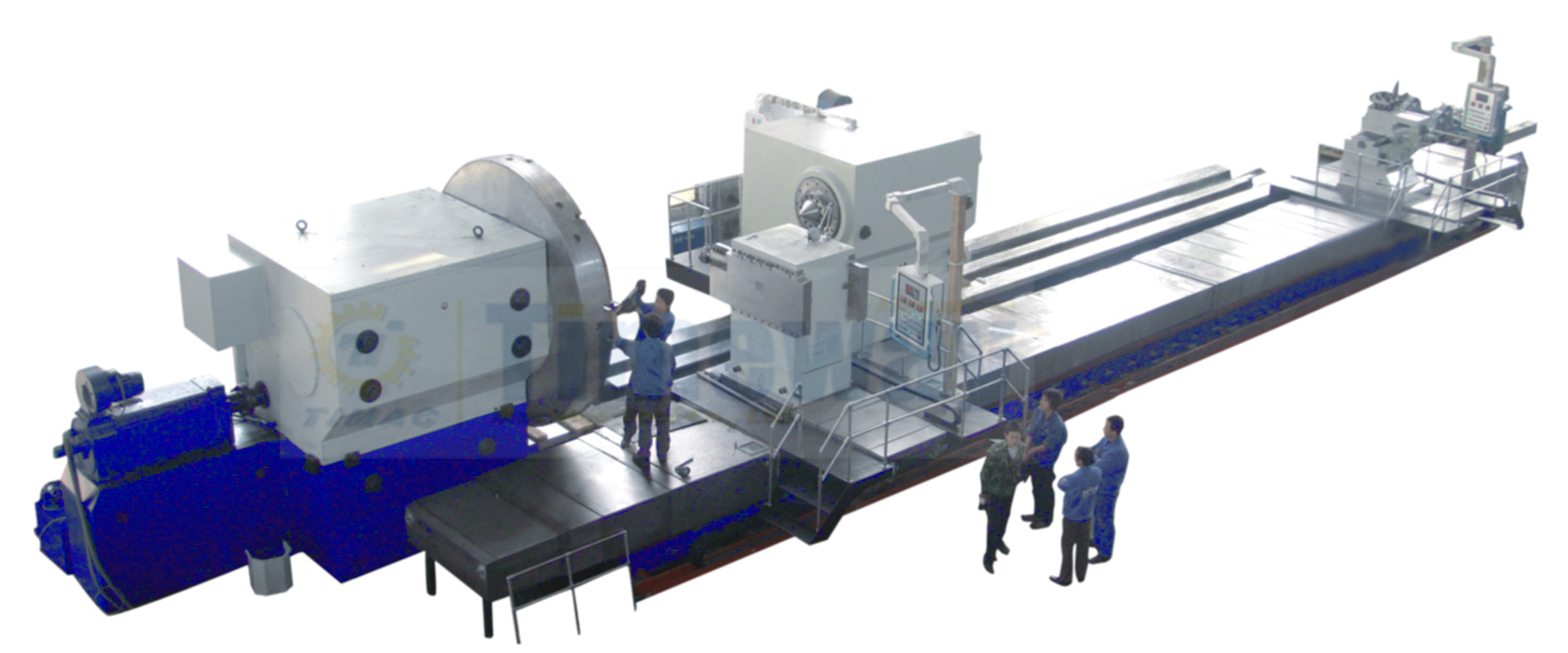

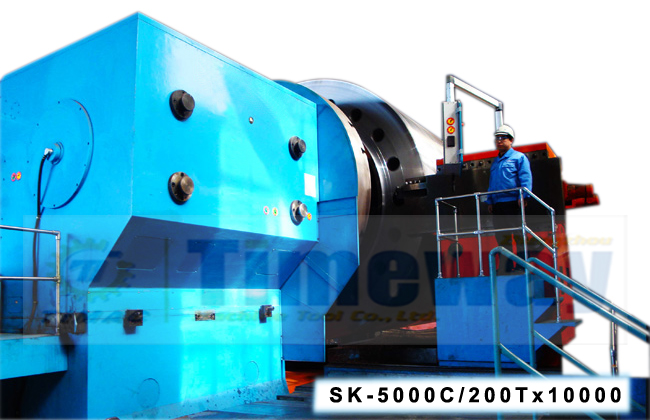

This series extra heavy duty horizontal lathe is the most advanced lathe adopted with the famous Germany technology. Adopting the most advance technology in both domestic and worldwide, the lathe owns the features of high precision, high rigid, high stability, and long term precision keeping, on the top level of the same type machines. The main transmission system and feeding system adopts separate type structure. It can finish the high precision and high efficiency turning work for the workpiece like cylindrical, inner hole, end surface, cone surface, screw(outer & inner), round arc, groove, etc.

This lathe comprise with all the parts of carriage bed, workpiece bed, headstock, tailstock, saddle, toolpost, DRO system, steady rest, and electrical control unit, etc. The bed includes workpiece bed and carriage bed, with separate structure. The tailstock and the steady rest can move on the workpiece bed, the toolpost moves on the carriage bed, and there are support chains for the toolpost and tailstock.

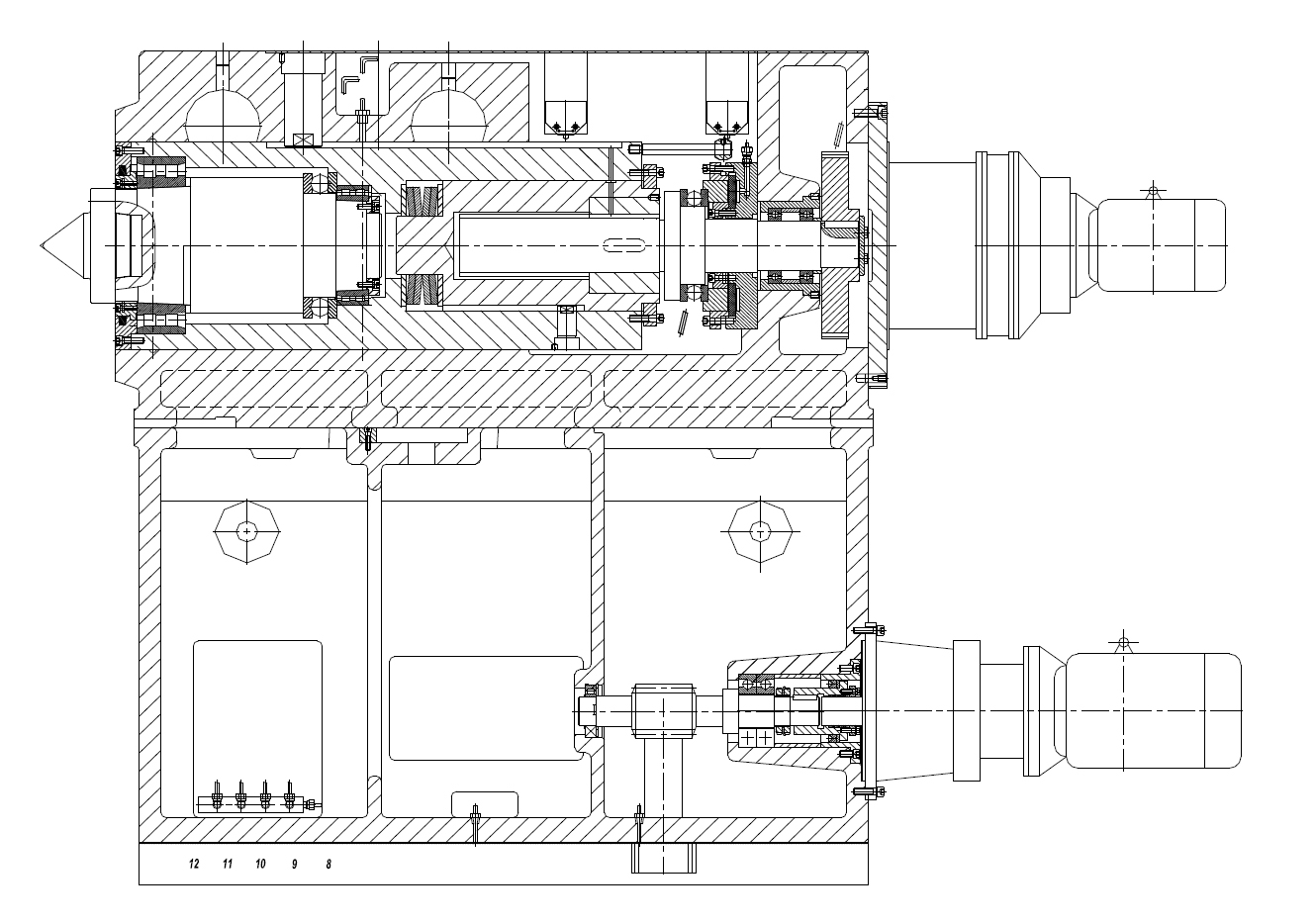

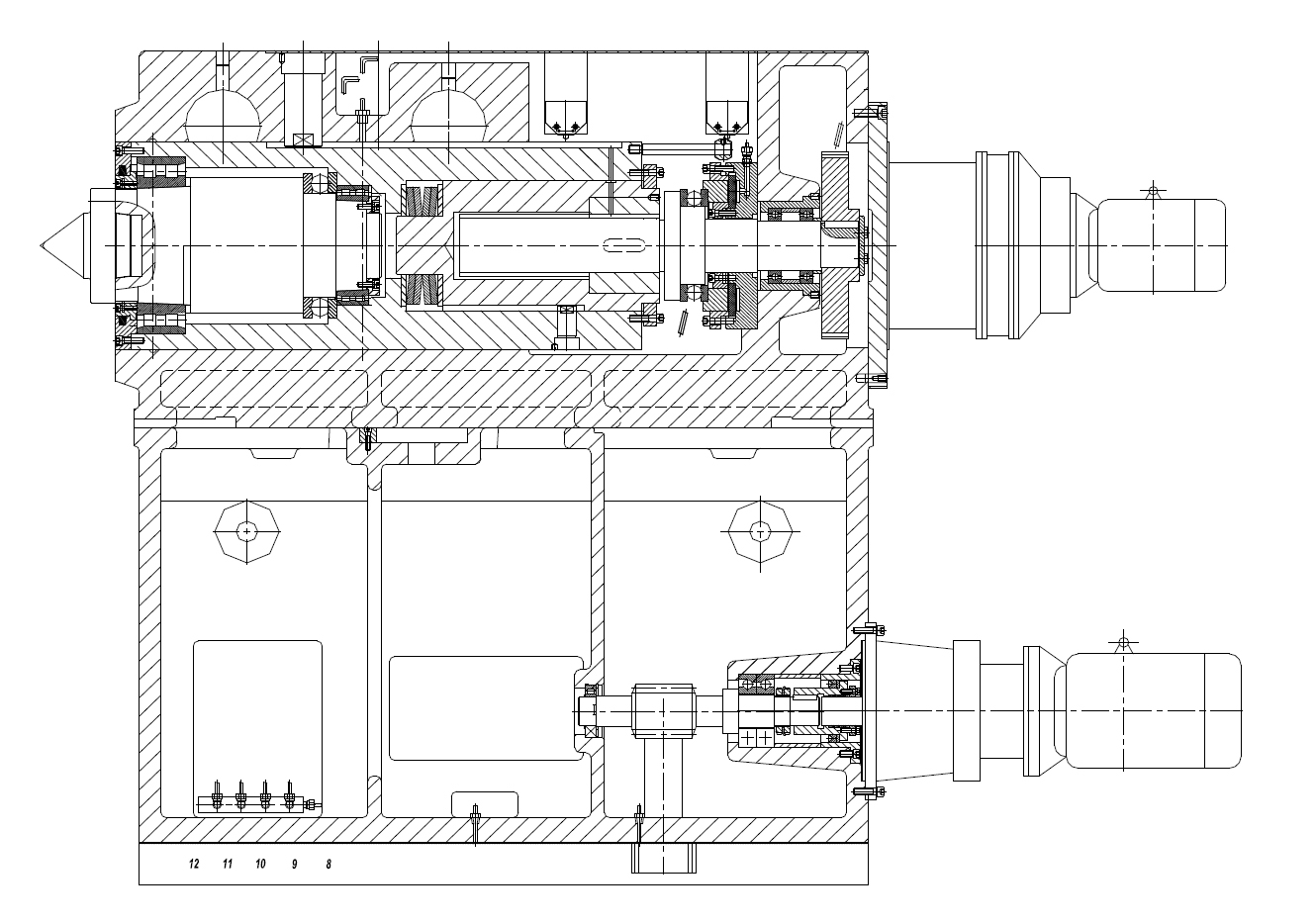

1. The overall thick-walled closed headstock, large diameter, short spindle, high precision spindle rotation system, and the use of independent thermostat oil cooling.

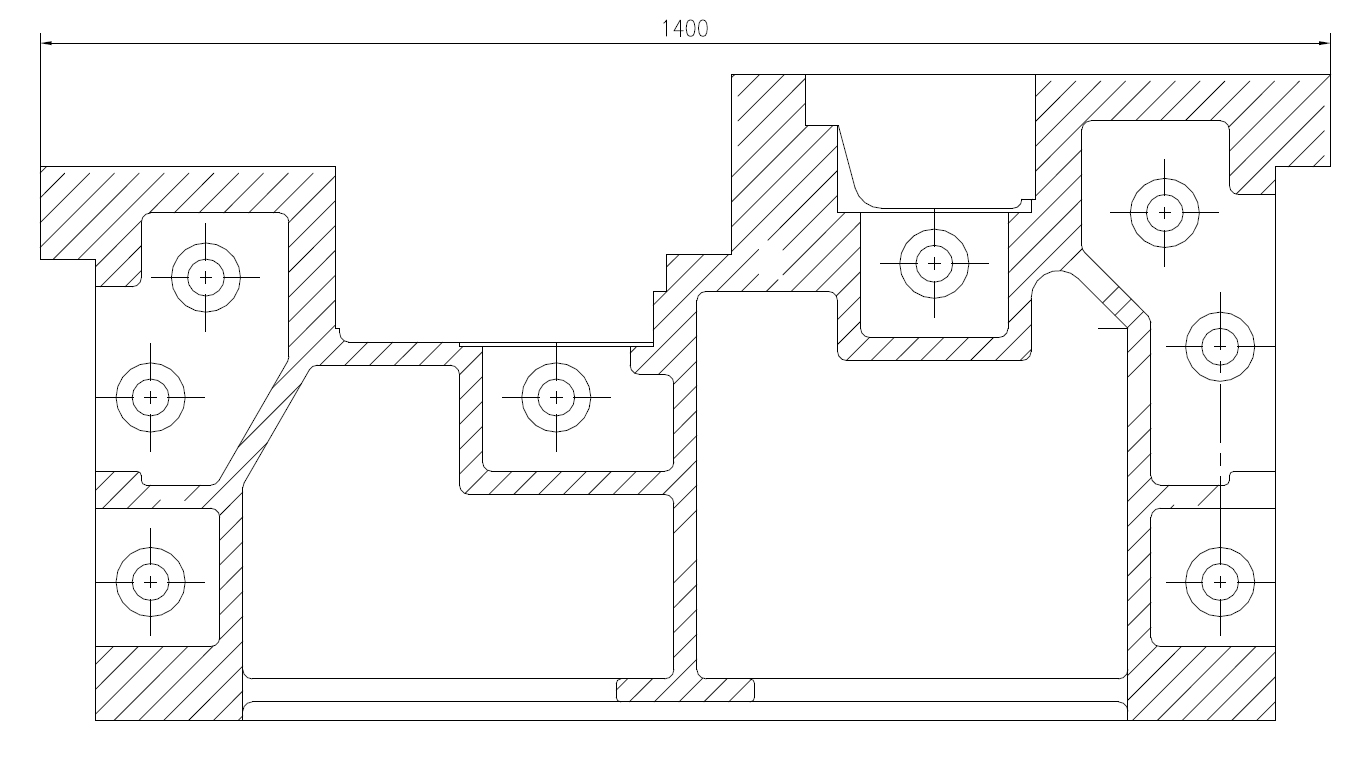

2. The bed includes workpiece bed and carriage bed, with separate structure. The tailstock and the steady rest can move on the workpiece bed and connect the headstock, the toolpost moves on the carriage bed. There are telescope type protection covers.

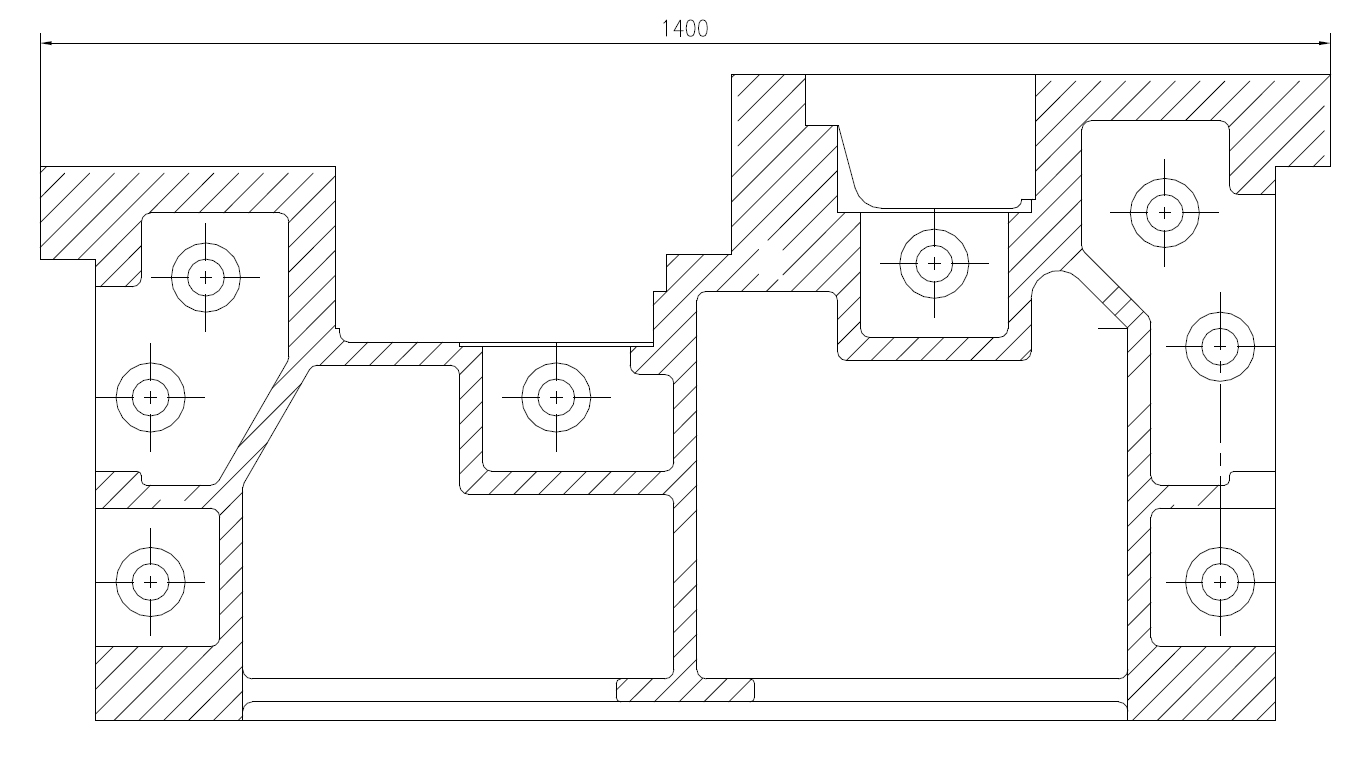

3. Separated type bed structure and expanded guideway width make the best force absorbing condition.

4. Since the two beds are separated, the possible deformation of the worpiece bed caused by the heavy workpiece can not affect the carriage bed, which insures the high precision of the carriage bed.

5. The separated type bed structure can reduce the reciprocal affect of cutting quake to the headtock and toolpost visually, and also can reduce the reciprocal affect of thermal deformation, so as to increase the machine’s anti- quake ability and working precision.

6. There are one row of foundation bolts and wedges every 500mm between the two beds, and all the wedges’ adjusting surface are ground, which increases the connecting rigid between the bed and ground. The elastic unit of the foundation bolts ensures the long term stability of the geometric precision of the machine, and increases the work precision and life.

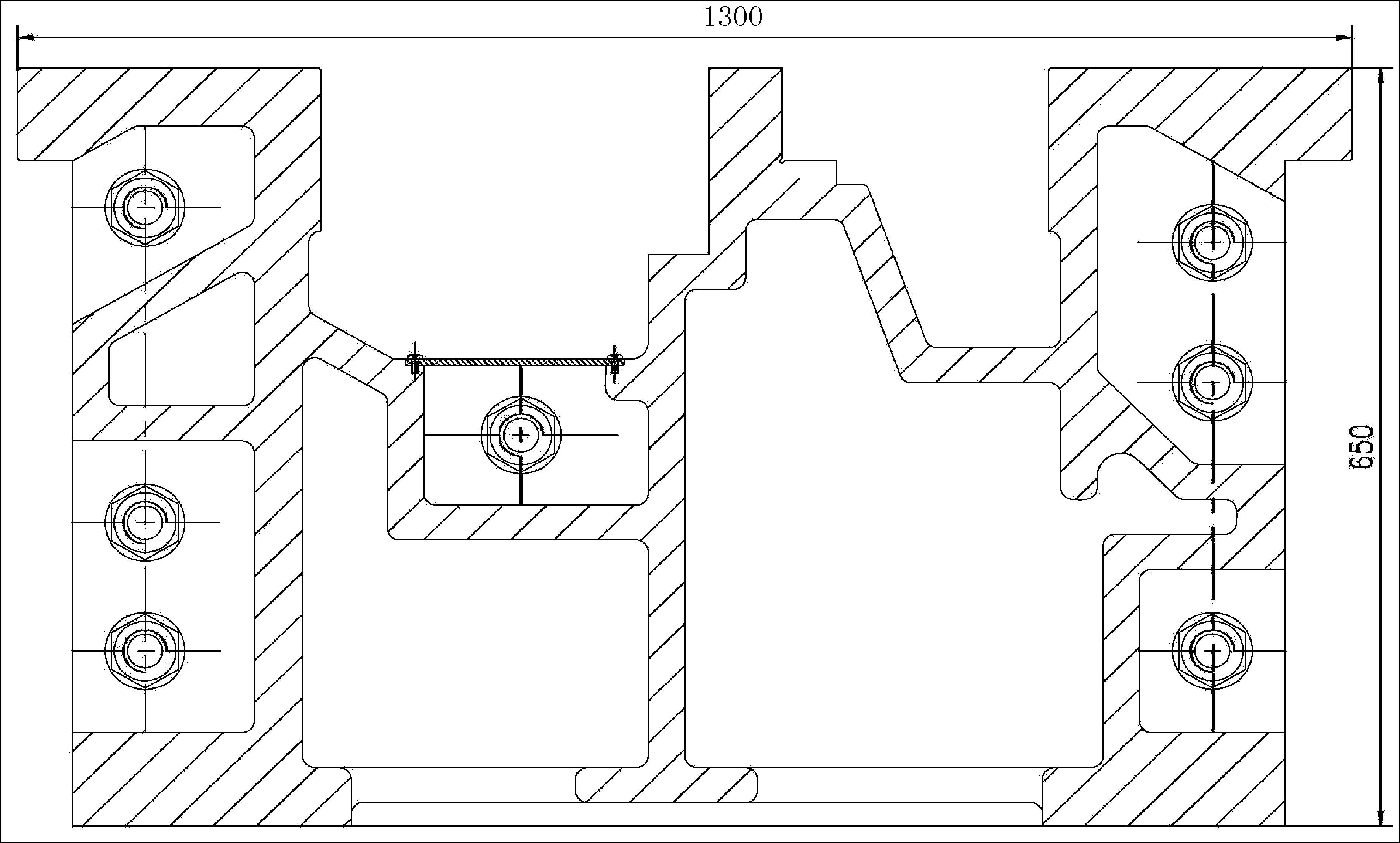

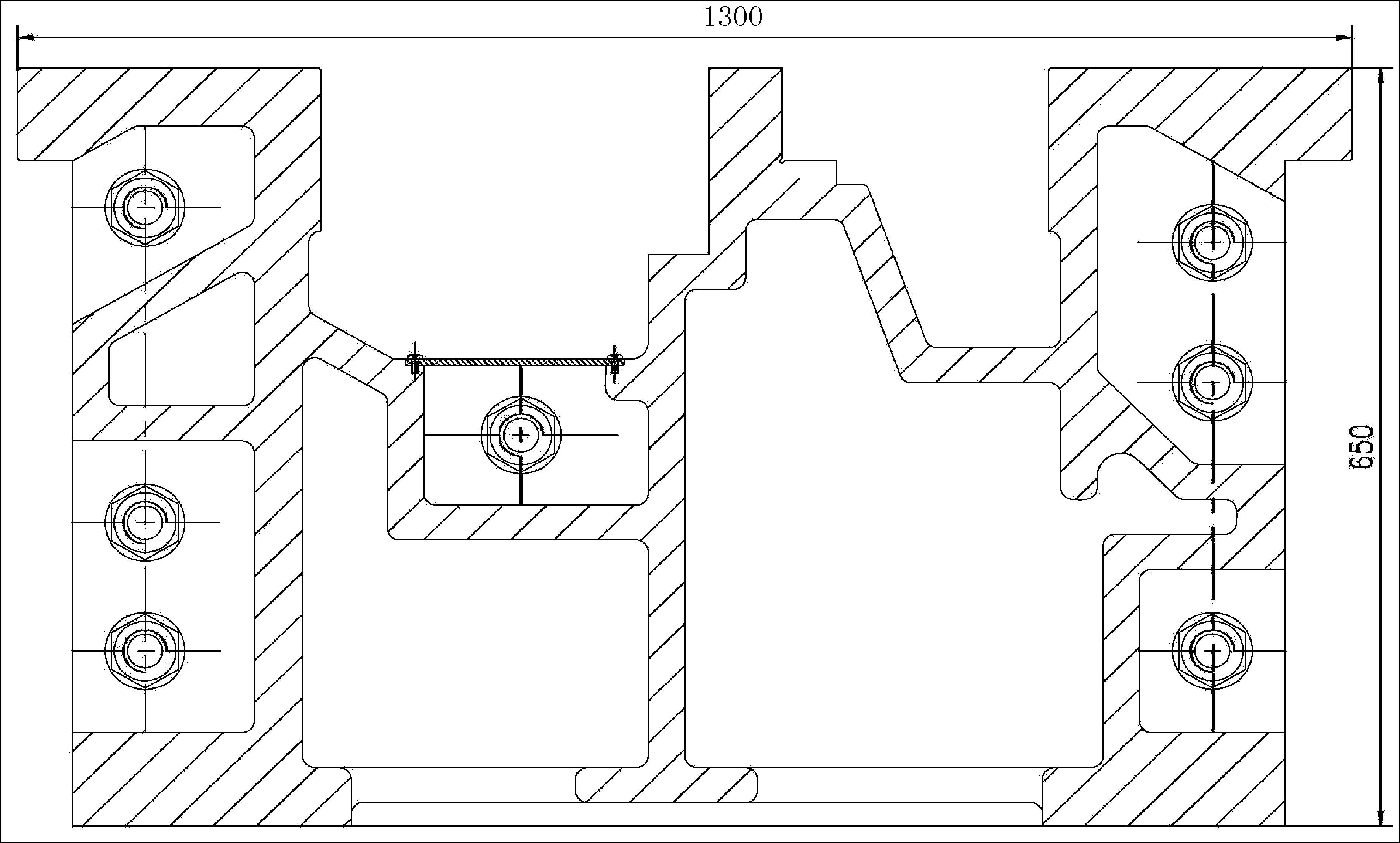

7. The two beds adopt high strength and low stew casting iron, both the width of the two beds is 1600mm, and the guideways were all ground on the high precision guideway grinding machine, which make sure the very good precision of guideways.

8. High precision spindle rolling bearings effectively guarantee the accuracy of rotation.

9. Tailstock using split box-type structure, tailstock sleeve and spindle are large diameter and high-precision structures, and center is large diameter and short taper forming, heavy carrying capacity and high precision turning.

10. Main parts structure was designed by finite element analysis, with good static and dynamic characteristics, to optimize state. The main castings are resin sand molding, high-frequency electric furnace smelting iron with high strength and low stress, and pass annealing, vibrating, and times aging stress relief methods, allowing the machine to get a very good stiffness, maximize the elimination of the material and structural stress, long-term stability of the machine precision can be guaranteed.

11. Headstock and feed box are processed on imported CNC boring and milling machines and machining centers, its roundness, concentricity, parallelism of axes have been strictly controlled.

12. Bed guideways, shafts, gears and other parts are all after heat treatment, and precision ground, which improves the transmission accuracy of the machine.

13. The machine can come with DRO system as requirement, which can display the longitudinal and cross moving distance.

14. The machine can be equipped with close open type steady rest according to user needs.

Workpiece bed Carriage bed Tailstock