| Specification | Unit | Q-280A | Q-330 | Q-390 | Q-440A | Q-520 |

| Max. Swing over bed | mm | 1000 | ||||

| Max. Swing over carriage | mm | 610 | ||||

| Distance between two centers | mm | 1500, 3000 | ||||

| Width of bed | mm | 755 | ||||

| Diameter of spindle inner hole | mm | 280 | 330 | 390 | 440 | 520 |

| Max. Clamped pipe diameter | mm | 130-273 | 190-320 | 190-380 | 273-426 | 330-510 |

| Step of spindle speed | - | 12 | 12 | 9 | 9 | 9 |

| Range of spindle speed | r.p.m | 16 to 380 | 7.5 to 280 | 6 to 205 | 4.9 to 180 | 6 to 205 |

| Kind of Metric thread and range | mm | 30kinds, 1 to 30 | 23kinds, 1 to 15 | |||

| Kind of Inch thread and range | teeth/in. | 27kinds, 1 to 28 | 22kinds, 2 to 28 | |||

| Kind of Longitudinal Feed and range | mm | 40kinds, 0.1 to3 | 32kinds, 0.1 to 1.5 | |||

| Kind of Cross Feed and range | mm | 40kinds, 0.05 to1.5 | 32kinds, 0.05 to 0.75 | |||

| Tool section ( H×W ) | mm | 45×45 | ||||

| Max. Travel of tool post | mm | 300 | ||||

| Max. Travel of cross slide | mm | 520 | ||||

| Diameter of tailstock sleeve | mm | 140 | ||||

| Travel of tailstock sleeve | mm | 300 | ||||

| Taper of tailstock sleeve | - | MT6 | ||||

| Main motor power | kw | 22 | 37 | |||

| Rapid motor power | kw | 1.5 | ||||

| Coolant pump | kw | 0.15 | ||||

| Overall size ( L x W x H) | mm | (4600, 6100)×2200×1520 | (5000, 6500)×2200×1600 | (5000, 6500)×2200×1650 | ||

| Weight | kg | 10500, 13500 | 11500, 14500 | 11500, 14500 | 13000, 15000 | 15000, 17000 |

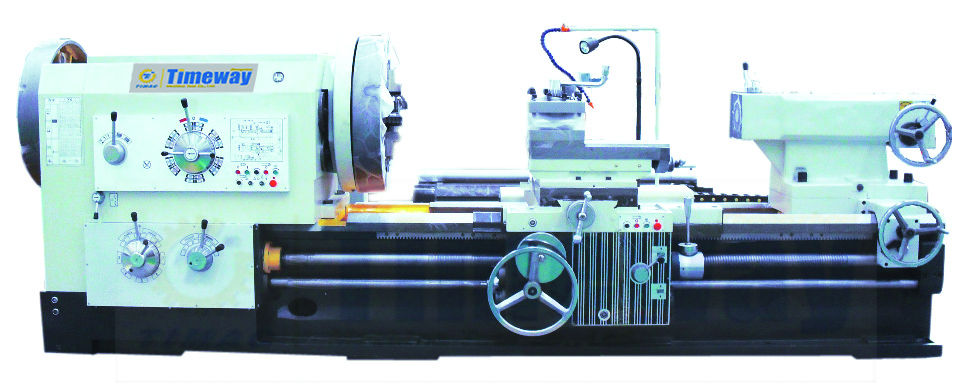

Pipe Threading Lathe (Q-280A, Q-330, Q-390, Q-440A, Q-520)

Features:

• The lathes are used for turning pipe threads, inside and outside, which are suitable for making external circles, holes and end surfaces of shafts or discs as general machine tools.

• Massive headstock with precision spindle running in tapered roller bearings, 2 lathe chuck mounts on both sides.

• High torque at the working spindle ensures high chip removal rates when machining parts with large diameters.

• Heavy machine bed made of premium cast-iron with hardened and ground guideways.

• Central, practical controls for feeds and thread leads.

• Wide spectrum of inch and metric threads.

• Heavy-duty 4-station tool holder

• Gears are hardened and ground

• Coolant system is included

Standard Accessories:

4 jaw big hole chuck (front and rear), Strady rest, follow rest, Taper turning attachment, Out board support, Oil gun, Coolant system, Work light, General tools, Foundation bolts, Operation manual (English edition)

Optional Accessories:

2-axes digital readout system (D.R.O)