Features:

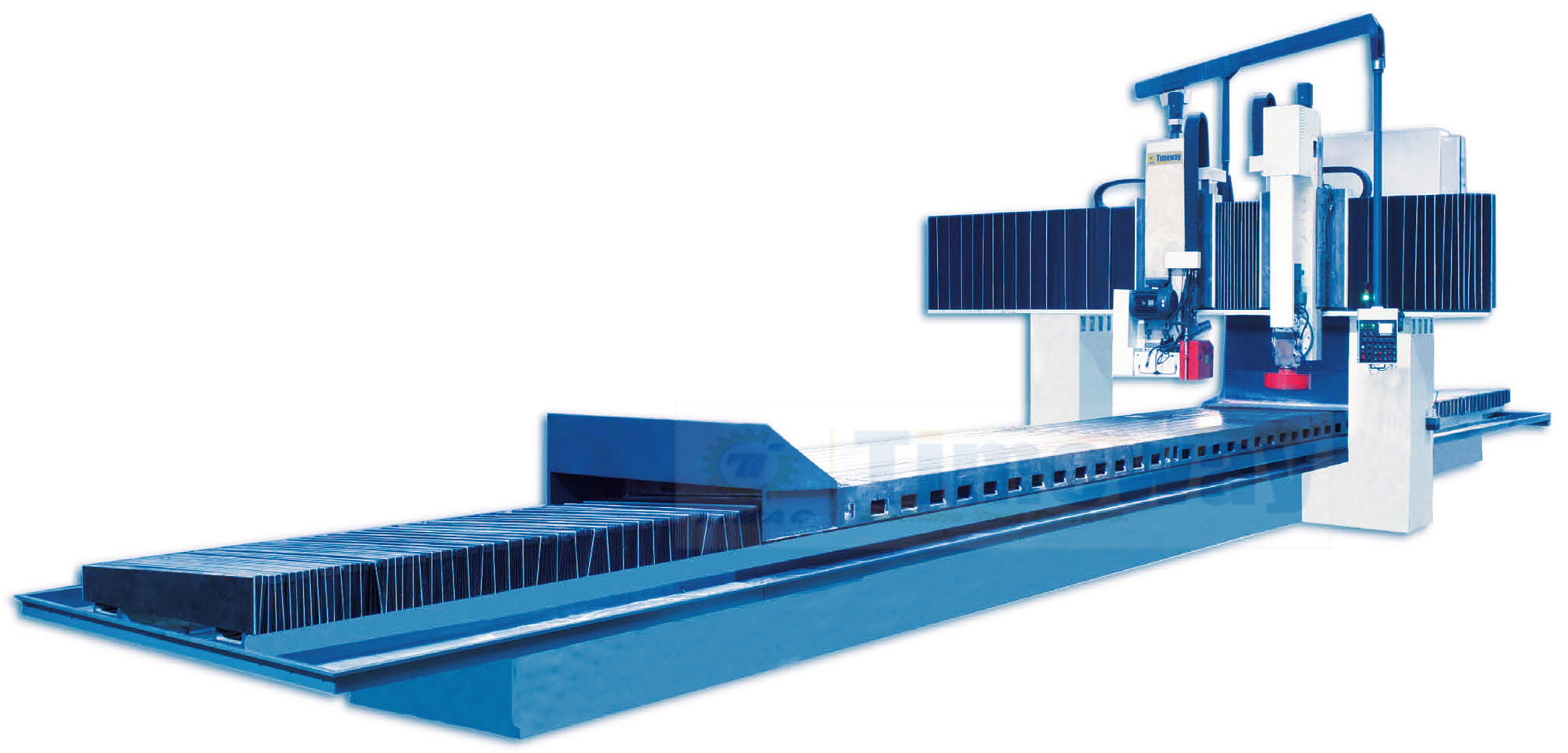

1. This model gantry grinding machine controlled by PLC is special to grind big parts, suitable for machining industry, mould industry and motor industry.

2. The bed, double columns and fixed bridge beam constitute closed rigidity gantry frame structure. Double V slide way structure is adopted on bed, and way of table is coated with Teflon, And box slide way is adopted on beam cross direction (Y-axis) and with good rigidity. There are two cross slide plate on the beam, The cross slide plates can move along the beam slide way, the vertical sliding ram can move along box slide way on the cross sliding plate way in vertical direction, also the box way of ram is coated with Teflon too, one horizontal grinding head are separately fixed on two vertical sliding ram.

3. The standard grinding heads include one horizontal grinding head.

4. The Horizontal Hydro-static & Hydro-dynamic bearing wheel head is drove by AC motor via multiple V-belt. The pulley of spindle adopts unload structure in order to reduce the vibration and improve grinding surface accuracy 。

5. Table moving is drove by hydraulic cylinder system with two piston rod, the speed could be remotely adjusted by a ratable throttle valve, the table move smoothly with low noise. The oil tank is independent one and equipped with oil cooler apparatus.

6. Grinding wheel head cross movement(Y axis) is drove by ball screw, this ball screw is drove by AC servo motor via belt reducer and controlled by PLC, this structure can realize intermittent feed, micro feed, variable speed changing function. The Y-axis movement also could be controlled by MPG ( electro hand wheel) and make operation easy。

7. Grinding wheel head vertical movement (Z axis) is drove by ball screw, the ball screw is drove by AC servo motor via a planetary gear reducer box and controlled by PLC, this structure can realize auto down feed, micro feed, variable speed changing function. The Z-axis movement also could be controlled by MPG (electro hand wheel) and make manual feed easy.

8. This machine is with Auto dimension-set grinding function. The operator can set the rough grinding feed rate and times, fine grinding feed rate and times, spark out grinding times, then the machine could automatically finish all the machining steps, after that the table will automatically stop to left and the wheel head go up to original position in order to unload or load work piece . The hydraulic pump power supply will automatically be shut down. This Auto grinding function make the operating is easy, greatly improve the efficiency. The operator could set the cross and longitudinal transverse distance on the Control panel instead of adjusting the mechanical reversing stop block, it makes the operating is easy with high efficiency.

9. The machine with Auto annunciator, when the lubricant pressure is too low, the grinder would stop auto and give an alarm.

10. The machine equipped with magnetic separator coolant tank. The coolant is collected back into tank. Magnetic separator is fixed on the top of tank.

11. The machine equipped with SIEMENS PLC controller, and some grinding actions are programmed input the PLC. All the function could be realize on the Center Control panel which equipped with a Touch operating display screen, make the operating is easy. The Center control panel is located on the beam and could move leftward or rightward, the operator could control the grinder on both sides.