Features:

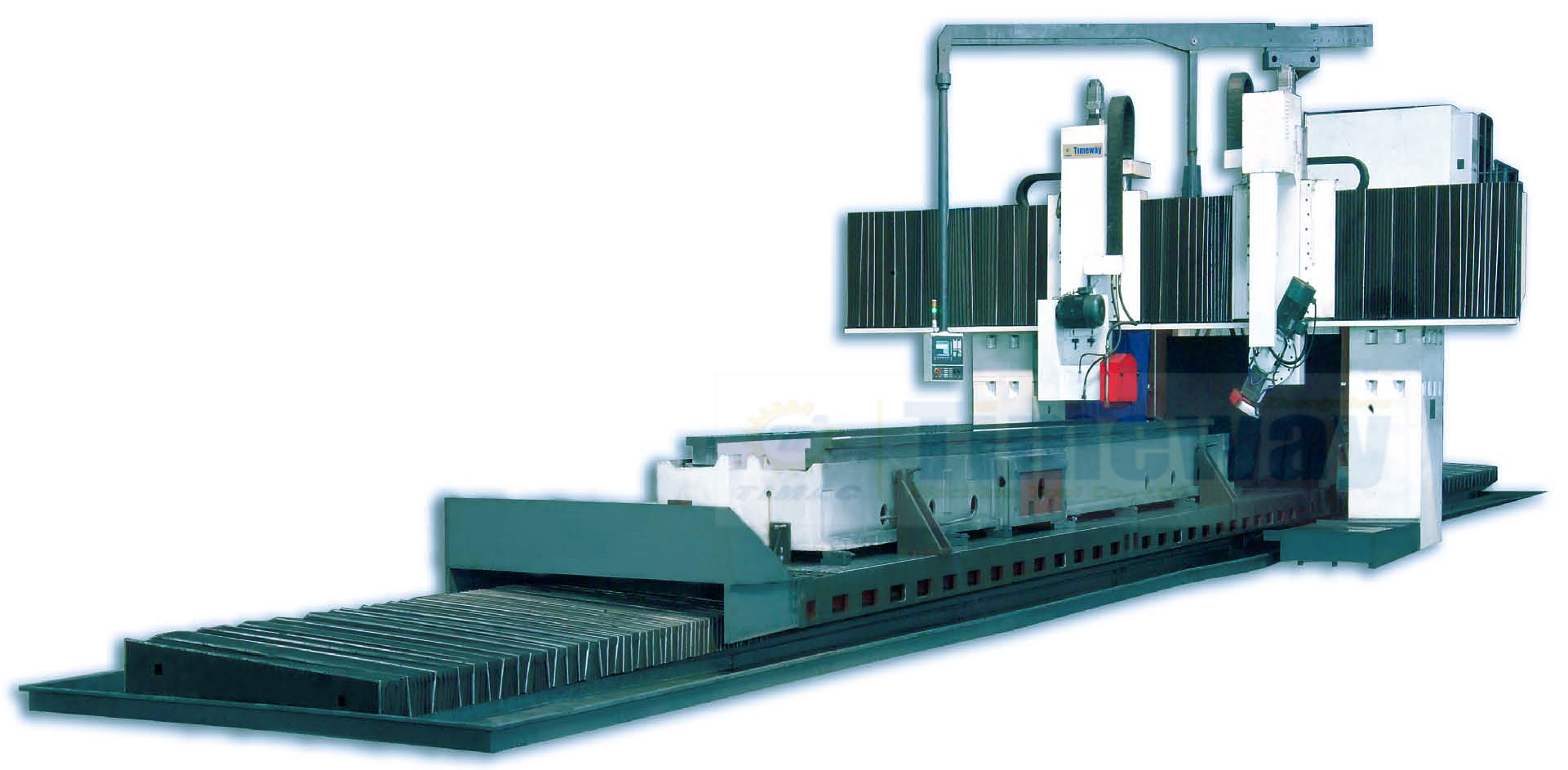

1. This model CNC double column surface grinding machine is special for ground big parts surface. The work-piece can be fixed on the table surface or electrical magnetic chuck. (the electrical magnetic chuck is optional)

2. The bed, double column and fixed bridge beam constitute enclosed rigidity gantry frame structure. Double V self-alignment slide way structure in adopted on bed, and slide way of table is coat with Teflon, “BTN” un-wearable coating. Box slide way is adopted on beam cross direction (Y-axis) with good rigidity, the guide is make of hardened alloy steel, stuck and screwed on the structure. The cross sliding saddle moving along the beam slide way, the vertical sliding ram which with box slide way make vertical feed along the cross sliding saddle way, also the box way of ram is coated with Teflon, “BTN” un-wearable coating too.

3. Table moving is drove by hydraulic cylinder system with two piston rod, the speed could be remote adjusted by a ratable throttle valve, the table moving smoothly, low noise. The oil tank is separate and equipped with oil cooler apparatus.

4. Wheel head cross moving(Y-axis) is drove by ball screw, the lead ball screw is drove by AC servo motor and controlled by PLC, this structure can realize space grinding, intermittent feed, micro feed, variable speed changing function. MPG equipped for manual feed.

5. Wheel head vertical moving(Z-axis) is drove by ball screw, the lead ball screw is drove by AC servo motor and controlled by PLC, this structure can realize intermittent feed, micro feed, variable speed changing function. MPG equipped for manual feed. Eliminates distortion resulted from self-weight of ram, the Z axis movement hydraulic cylinder balancing device is equipped, decrease the un-load toque of the ball screw then reduce the wear out of ball screw and keep the stability accuracy.

6. Horizontal Hydro-static & hydro-dynamic bearing wheel head is drive by motor via multiple V-belt. The pulley of spindle unit is equipped with unload apparatus in order to reduce the vibration and get high accuracy finishing surface.

7. The machine equipped with Siemens SINUMERIK 828Dsl controller for the Y & Z axes moving, which are both drove by Siemens AC servo motors and drivers.

8. The machine gives alarm signal auto, while the lubricant shortage, pressure is too low, the grinder would stop auto and give an alarm.