| Specification | Unit | MDC3000TR | MDC4000TR | MDC5000R | MDC6000TR | |

| Table | ||||||

| Table size(W*L) | mm | 3000*(6000-36000) | 4000*(6000-36000) | 5000*(6000-36000) | 6000*(6000-36000) | |

| T-slot size | mm | 36-300 | 36-300 | 36-300 | 36-300 | |

| Max.load of table | kg | 15000 | 15000 | 20000 | 25000 | |

| Gantry effective width | mm | 4000 | 5000 | 6000 | 7000 | |

| Travel | ||||||

| X-axis travel | mm | 6000-36000 | 6000-36000 | 6000-36000 | 6000-36000 | |

| Y-axis travel | mm | 5000 | 6050 | 7050 | 8000 | |

| Z-axis travel | mm | 1500 | 1500 | 2000 | 2000 | |

| W-axis travel | mm | 1500 | 3000 | 3500 | 3500 | |

| Distance from Spindle end to workbench surface | mm | 0-3000 | 0-4500 | 0-5500 | 0-5500 | |

| Spindle | ||||||

| Taper | ISO50 | ISO50 | ISO60 | ISO60 | ||

| Spindle motor power | kw | 40/66 | 60/84 | 100/140 | 100/140 | |

| Speed range | rpm | 5-2500 | 5-1800 | 5-1600 | 5-1600 | |

| The section size of ram | mm | 530*550 | 620*650 | 620*650 | 620*650 | |

| Tool | ||||||

| Tool shank type | DIN50 | DIN50 | DIN60 | DIN60 | ||

| Rivet type | DIN69872 D50 | DIN69872 D50 | DIN69872 D60 | DIN69872 D60 | ||

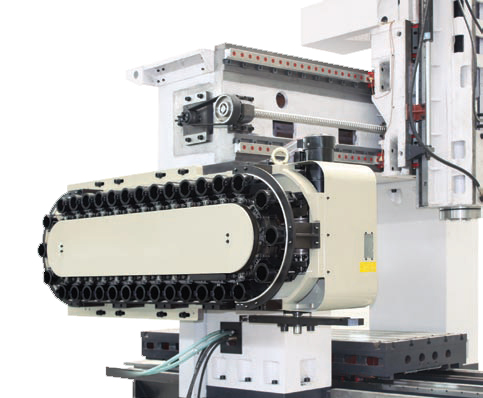

| Tool magazine | ||||||

| Capacity | T | 60 | 60 | 60 | 60 | |

| Tool change type | Random | Random | Random | Random | ||

| The time of tool change | sec. | 10 | 10 | 10 | 10 | |

| Max.size of tool | mm | Φ225*350 | Φ175*500 | Φ320*500 | Φ320*500 | |

| Max.weight of tool | kg | 20 | 20 | 20 | 20 | |

| Feeding | ||||||

| Feeding speed | X/Y/Z | mm/min | 1-8000 | 1-8000 | 1-8000 | 1-8000 |

| W | mm/min | 5-2000 | 5-2000 | 5-2000 | 5-2000 | |

| Rapid feeding speed | X/Y/Z | mm/min | 10000 | 10000 | 10000 | 10000 |

| W | mm/min | 2000 | 2000 | 2000 | 2000 | |

| Accuracy | ||||||

| Positioning precision | X | mm | 0.02/2000 | 0.02/2000 | 0.02/2000 | 0.02/2000 |

| Y | mm | 0.04 | 0.04 | 0.04 | 0.05 | |

| Z/W | mm | 0.02/0.025 | 0.02/0.025 | 0.02/0.03 | 0.02/0.03 | |

| Repeat positioning precision | X | mm | 0.01/2000 | 0.01/2000 | 0.01/2000 | 0.01/2000 |

| Y | mm | 0.016 | 0.016 | 0.016 | 0.016 | |

| Z/W | mm | 0.014 | 0.014 | 0.014/0.015 | 0.014/0.015 | |

| Machine weight | kg | 168000(Table length 6m) | 440000(Table length 24m) | 504000(Table length 24m) | 540000(Table length 24m) | |

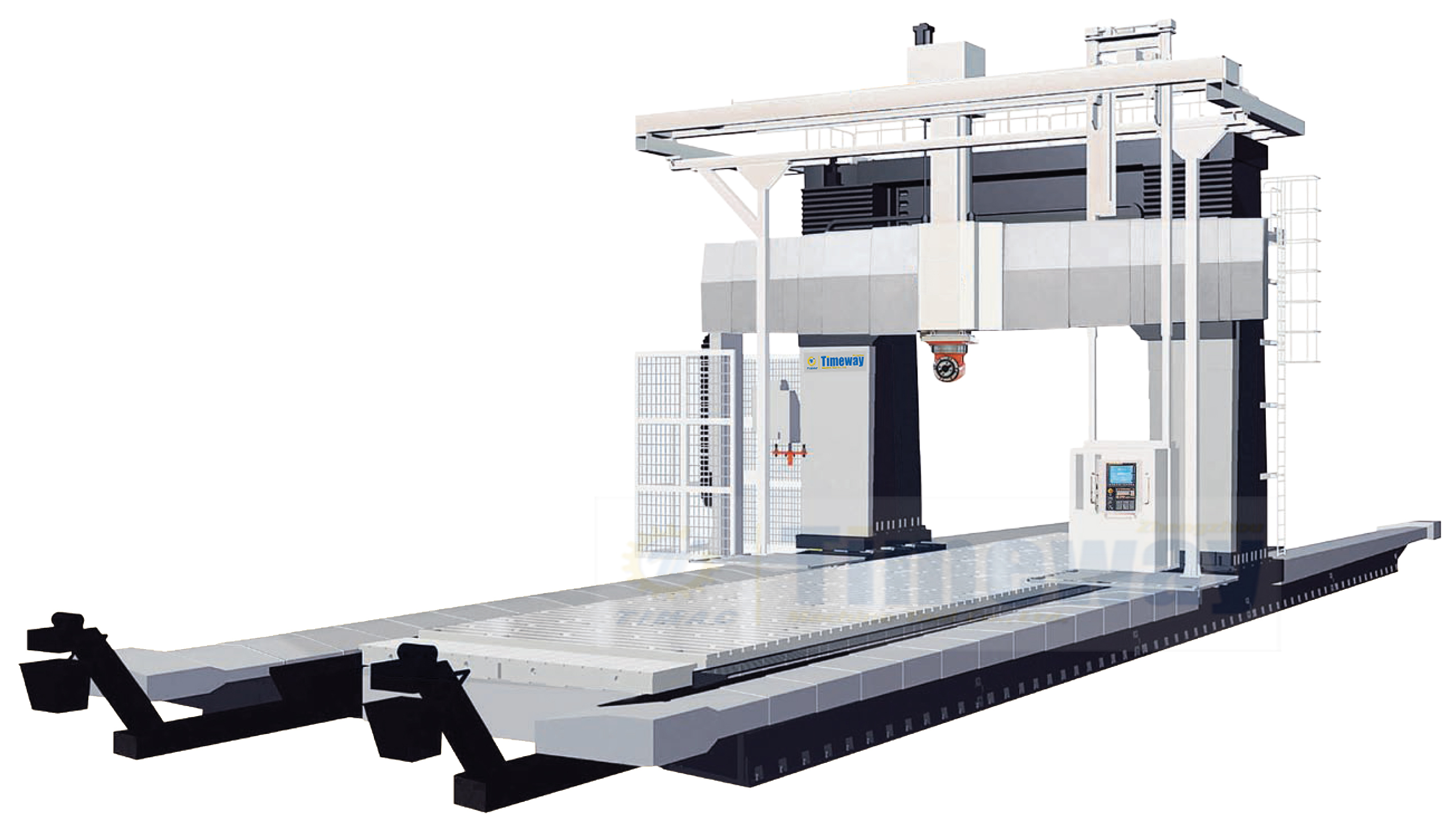

CNC Double Column Machining Center (Beam & Gantry Moving)

Features:

Machine Structure:

The machine tool layout form of moving gantry frame, lifting beam and fixed table, gantry frame makes X-axis movement along bed, beam makes W-axis movement on the column, ram makes Z-axis vertical movement up and down on the around-type slide, slide and ram as a whole makes Y-axis movement on the beam.

Machine Use Range:

It is suitable for large parts processing of aerospace,railway locomotive, war industry, chemical industry, shipbuilding, metallurgy, energy, machine tool, mould and other industries. After loading and clamping woekpiece one time, it can automatically high-efficiency and high-precision continuously finish parts'five-surface processing multi proceduces of milling, drilling, tapping and etc, it can process plane, hole series, inclined plane, inclined holes, grooves, cavities for all kinds of steel and non-ferrous metal parts.

Machine Features:

1. The machine tool adopts six national invention and utility model patent technology.

2. All axis use closed loop control,guaranteeing machine tool positioning precision and the stability of precision.

3. The machine tool has large-power cutting and the high-efficiency of rough machining,at the same time fine machining.

4. When X-axis travel is during 4200-6200mm, it adopts supper length screw auxiliary support technology.

5. When X-axis travel is greater than 4200mm, it adopts multi period of bed joint technology.

Optional configuration:

Tool magazine

Right-angle milling head

Universal milling head

Lengthen milling head

Manual Milling Heads:

Auto. Milling Heads: