| Specification | Unit | DMC2000TR | DMC2500TR | DMC3000TR | |

| Table | |||||

| Table size(W*L) | mm | 2000*6300 | 2500*6300 | 3000*6300 | |

| Worktable length optional range | mm | 4000-12000 | 4000-12000 | 4000-12000 | |

| T-slot size | mm | 9-28-200 | 13-28-200 | 15-28-200 | |

| Max.load of worktable | kg | 33000 | 35000 | 42000 | |

| Gantry effective width | mm | 2550 | 3050 | 3550 | |

| Travel | |||||

| X-axis travel | mm | 6500 | 6500 | 6500 | |

| Y-axis travel | mm | 3200 | 3700 | 4200 | |

| Z-axis travel | mm | 800(1000) | 800(1000) | 800(1000) | |

| W-axis travel | mm | 1300 | 1300 | 1300 | |

| Min.distance from spindle center to worktable surface | mm | 150 | 150 | 150 | |

| Spindle | |||||

| Taper | BT50 | BT50 | BT50 | ||

| Speed range | rpm | 20-3000 | 20-3000 | 20-3000 | |

| Spindle motor power | FANUC | kw | 22/26 | 22/26 | 22/26 |

| SIEMENS | kw | 22/30 | 22/30 | 22/30 | |

| Max.output torque of straight milling head | N.m | 2000 | 2000 | 2000 | |

| Max.output torque of right-angle milling head | N.m | 1100 | 1100 | 1100 | |

| The section size of ram | mm | 450*450 | 450*450 | 450*450 | |

| Tool magazine | |||||

| Capacity | T | 50 | 50 | 50 | |

| Tool change type | Random | Random | Random | ||

| Max.size of tool | mm | 350*Φ125 | 350*Φ125 | 350*Φ125 | |

| Max.weight of tool | kg | 25 | 25 | 25 | |

| Feeding | |||||

| Feeding speed | mm/min | 1-8000 | 1-8000 | 1-8000 | |

| Rapid feeding speed | X/Y | mm/min | 15000 | 15000 | 15000 |

| Z | mm/min | 10000 | 10000 | 10000 | |

| W | mm/min | 2000 | 2000 | 2000 | |

| Accuracy | |||||

| Positioning precision | X | mm | 0.026(Closed-loop) | 0.026(Closed-loop) | 0.026(Closed-loop) |

| Y | mm | 0.02(Closed-loop) | 0.02(Closed-loop) | 0.02(Closed-loop) | |

| Z | mm | 0.013(Closed-loop) | 0.013(Closed-loop) | 0.013(Closed-loop) | |

| W | mm | 0.016(Closed-loop) | 0.016(Closed-loop) | 0.016(Closed-loop) | |

| Repeat positioning precision | X | mm | 0.013(Closed-loop) | 0.013(Closed-loop) | 0.013(Closed-loop) |

| Y | mm | 0.013(Closed-loop) | 0.013(Closed-loop) | 0.013(Closed-loop) | |

| Z | mm | 0.01(Closed-loop) | 0.01(Closed-loop) | 0.01(Closed-loop) | |

| W | mm | 0.011(Closed-loop) | 0.011(Closed-loop) | 0.011(Closed-loop) | |

| Machine weight | kg | 102000 | 110000 | 132000 | |

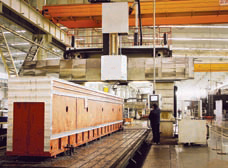

CNC Double Column Five-faces Machining Center (Beam&Table Moving)

Features:

Structure:

The series machine is beam lifting, worktable movement, gantry frame-type machining center. On the basis of inheriting traditional gantry strong rigidity, good stability and etc characteristics, our factory introduce and absorbs advanced industrial design idea, use the finite element method to take mechanical analysis, reasonable distributed muscle, reasonable distributed quality, which can guarantee the strong rigidity, static precision and dynamic preformance stability and reliable. It has advanced level in the same kind machine, is a kind high efficiency, high precision, high reliable advanced equipment.

The series machine has the characteristics of high modularization degree, parts versatility, full-closed loop control, excellent performance. Machine tool is equipped standardly with straight milling head, also equipped optionally with auto. right-angle milling head and lengthened straight milling head, when selecting more than two milling head, the machine is equipped with milling head magazine. All milling head are installed in milling head magazine and automatically change. According to requirement,it can achieve workpiece measurement system, tools measurement system and other functions, to meet plane, curved surface and hole series procsessing requirement.

The machine tool with full automatic five-face processing only load and clamp workpiece one time, it can finish five-face processing of drilling, milling surface, tapping and etc. High rigid square ram spindle structure, it has speed 3000rpm and torque 2000N.m, and improve the machining efficiency, according to customers' requirement, we can add or delete configuration and provide a full range of solutions.

Machine Use:

The machine tool is widely used in general machinery, aviation, aerospace, automotive, nuclear industry, energy, mould, locomotive, juki, engineering machinery, ships, machinetools, electronics, printing, textile and other manufacturing industries.

1.When X-axis travel is during 4200-6200mm, it adopts super length screw auxiliary support technology.

2.When X-axis travel is greater than 4200mm,it adopts multi period of bed joint technology.

Manual Milling Heads:

Auto. Milling Heads: